Motor bearing life is assured by maintaining proper alignment and good lubrication at all times. Most of the new motor bearings are lubricated to provide 3-6 months of satisfactory service under normal operating conditions. Thereafter, re-lubrication is required. Here are some maintenance tips for re-lubricating.

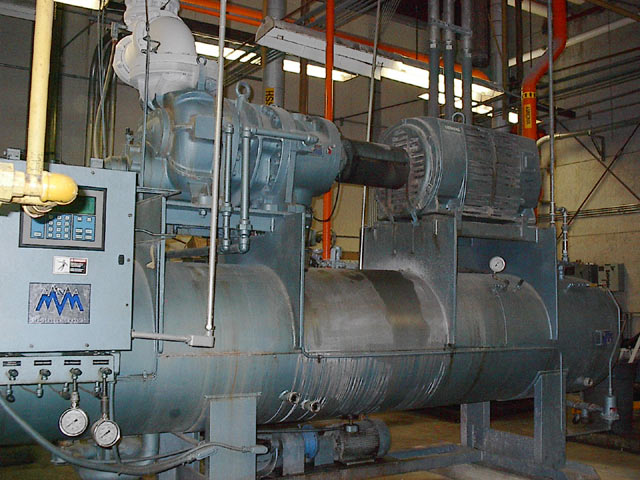

INDUSTRIAL SCREW COMPRESSOR MAINTENANCE

Motor Bearing Study

Motor Bearing Grease Up

| Motor Size | Less than 100 HP 143T-256T frame size |

125-350 HP 404TS-447TS frame size |

| Standard Duty: Up to 8 hours per day | 8 months | 8 months |

| Severe Duty: 24 hours per day | 4 months | 4 months |

| Note Above table is reference use only. Consult motor manufacturer for specific greasing interval. |

||

Type of Grease, Compatible or Incompatible.

It is common for several different greases to be used in the engine room. It is important to be aware of grease compatibility. Not all greases are fully compatible with one another because different types of thickeners and oil-bases are used. A mineral oil-base grease SHOULD NOT be mixed with a synthetic oil-base grease. The table below shows commonly used greases for motor bearings, their oil-base and their thickener compatibility.

| Name of Grease | Type of Oil-Base | Type of Grease Thickener |

| Chevron SRI | Mineral | Polyurea |

| Exxon Unirex #2 | Synthetic | Lithium Complex |

| Exxon Polyrex | Mineral | Polyurea |

| Shell Dolium | Mineral | Polyurea |

| Citigo EP | Mineral | Lithium |

| Shell Alvania EP #2 | Mineral | Lithium 12-Hydroxy |

| Aluminum Complex | Barium | Calcium | Calcium 12 Hydroxy | Calcium Complex | Lithium | Lithium 12 Hydroxy | Lithium Complex | Polyurea | |

| Aluminum Complex | X | X | O | X | X | X | O | X | |

| Barium | X | X | O | X | X | X | X | X | |

| Calcium | X | X | O | X | O | ♦ | O | X | |

| Calcium 12 Hydroxy | O | O | O | ♦ | O | O | O | X | |

| Calcium Complex | X | X | X | ♦ | X | X | O | O | |

| Lithium | X | X | O | O | X | O | O | X | |

| Lithium-12 Hydroxy | X | X | ♦ | O | X | O | O | X | |

| Lithium Complex | O | X | O | O | O | O | O | X | |

| Polyurea | X | X | X | X | O | X | X | X | |

| O=Compatible ♦=Borderline Compatibility X= Incompatible | |||||||||

Because motor manufacturers specify different types of grease for their motors, errors in mixing incompatible greases can take place easily. If a motor is being repaired in-service, shop grease may be used that the engine room does not stock.

There are several good practices you may implement in order to prevent these errors from occurring.

- Use color-coordinated grease guns (color sleeves are available.) and grease nipple tags.

- Store greases in an organized manner (location, name tag, color coding, etc…).

- Specify the type of grease before the motor is sent to a service shop.

Brands We Work With

Do you have questions about compressor screws or need maintenance?

What Makes Us Different

With over 40 years of combined experience in engineering, manufacturing, servicing, and maintenance of screw compressor packages we can handle your all maintenance needs.