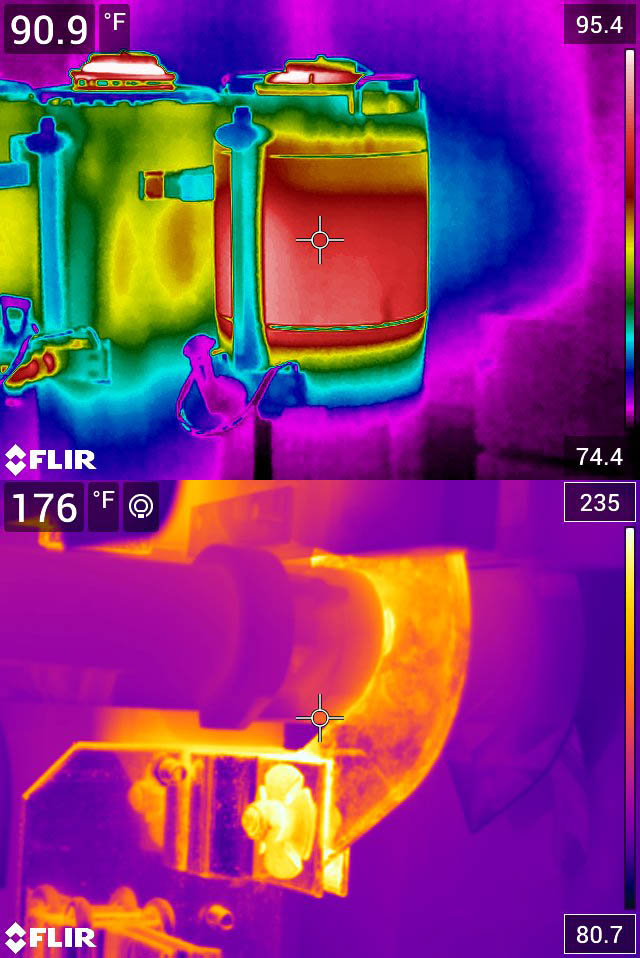

Significant damage may have already been inflicted on the equipment. Obviously, this can create costly emergency repairs and possibly considerable production loss. Infrared (thermal imaging) cameras are used to detect thermal problems during their developing stage.

Through new technology, thermal cameras are doing a better job of identifying heat problems in motors, starters, and control panels. This is to offer thermal imaging of motors, starters, control panels, and power distribution panels by a certified professional that is accessible, affordable, and dependable.

Early detection of electrical problems in your motors, starters, control panels, and power distribution panels, used with refrigeration systems, will reduce maintenance expenses and minimize production losses due to thermal problems. It is recommended that an inspection interval of every 6 months be implemented.